PLG series continuous plate dryer is a kind of high efficiency conducting and continuous drying equipment. Its unique structure and operating principle provide advantages of high heat efficiency , low energy consumption…

0086-18962409901

There are three major types: normal pressure type, closed type, and vacuum type; and four major models: 1200, 1500, 2200 and 3000; and three kind of material grades, A (carbon steel), B (use stainless steel for material contacted area), and C (use stainless steel for material contacted area, steam pipes, main shaft and supports, and linings for cylinder body and top cover).The drying area of the dryer is 4 to 180㎡. We have produced hundreds of models with auxiliary devices which are available to meet requirements of all customers.

(2) Easy to operate - Simple operation for turn on and turn off. - After material feeding is stopped, the remaining material inside of the machine can be easily discharged out by the harrows. - You can clean and observe inside from the large-scale viewing window.

(3) Low energy consumption - The material layer is thin and the rotary speed of main shaft is low, so it required low power and electricity consumption. - The material is dried by conducting heat, so it has high heating efficiency.

(4) Good operation environment - Normal pressure type: The speed of air flow inside of the machine is low and the humidity is high in upper end and low in bottom end, so the dust can’t float to the top which keeps no dust in the exhausted air. - Closed type: The machine is equipped with solvent recovery device which can recover organic solvent easily from the wet air. The solvent recovery device has a simple structure and high recovery rate. For the flammable, explosive and poisonous materials, the nitrogen can be used as medium for closed circulation and keeps a safe working condition. - Vacuum type: The plate dryer is operating under vacuum condition and it is particularly suitable for drying heat sensitive materials.

(5) Easy installation - The dryer is delivered in a complete piece so it is quite easy to install and fix at site. - The disc plates are being arranged by layers and it will be installed vertically, so it takes a small occupying area from the workshop.

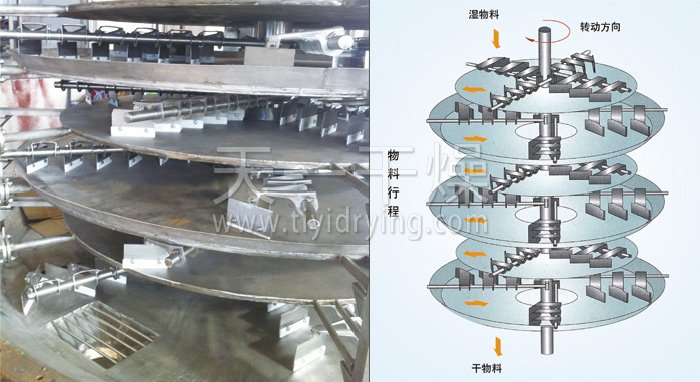

2. Material Transmission System - Revolution of main shaft: 1~10 rpm, electromagnetism or transducer timing. - Rake arm: 2 to 8 rake arms will be fixed on the main shaft on the every layer. - Rake blade: the rake blades are hinged to the rake arms and float with the surface of the plate. There’re several types of rake blades. - Roller: For the material that is easy to agglomerate, or required to be grinded, the rollers shall be placed at the appropriate place to reinforce the heat transfer and drying process.

3. Three types of dryer body: normal pressure, sealed, and vacuum - Normal pressure: The dryer body is cylindrical or octagonal and the structure can be integrated or separated. The ducting system for the heat source can be placed inside or outside of the dryer. - Sealed: The dryer body is cylindrical and it can bear the interior pressure of 5KPa. The ducting system for the heat source can be placed inside or outside of the dryer. - Vacuum: The dryer body is cylindrical and the design pressure is 0.1MPa. The ducting system for the heat source is placed inside of the dryer.

4. Air Heater The air heater is usually used to meet larger evaporation capacity requirements in order to increase drying efficiency.

| Item \ type | Diamter (mm) | High (mm) | Area of dry (m2) | Power (Kw) |

| 1200/4 | Φ1850 | 2718 | 3.3 | 1 |

| 1200/6 | 3138 | 4.9 | ||

| 1200/8 | 3558 | 6.6 | 1.5 | |

| 1200/10 | 3978 | 8.2 | ||

| 1200/12 | 4398 | 9.9 | 2.2 | |

| 1500/6 | Φ2100 | 3022 | 8.0 | |

| 1500/8 | 3442 | 10.7 | ||

| 1500/10 | 3862 | 13.4 | ||

| 1500/12 | 4282 | 16.1 | 3.0 | |

| 1500/14 | 4702 | 18.8 | ||

| 1500/16 | 5122 | 21.5 | ||

| 2200/6 | Φ2900 | 3319 | 18.5 | |

| 2200/8 | 3739 | 24.6 | ||

| 2200/10 | 4159 | 30.8 | 4.0 | |

| 2200/12 | 4579 | 36.9 | ||

| 2200/14 | 4999 | 43.1 | 5.5 | |

| 2200/16 | 5419 | 19.3 | ||

| 2200/18 | 5839 | 55.4 | 7.5 | |

| 2200/20 | 6259 | 61.6 | ||

| 2200/22 | 6679 | 67.7 | 11 | |

| 2200/24 | 7099 | 73.9 | ||

| 2200/26 | 7519 | 80.0 |

| Item \ type | Diamter (mm) | High (mm) | Area of dry (m2) | Power (Kw) |

| 2500/6 | Φ3150 | 3319 | 26.3 | 4 |

| 2500/8 | 3739 | 35 | ||

| 2500/10 | 4159 | 43.8 | 5.5 | |

| 2500/12 | 4579 | 52.5 | ||

| 2500/14 | 4999 | 61.3 | 7.5 | |

| 2500/16 | 5419 | 70 | ||

| 2500/18 | 5839 | 78.8 | 11 | |

| 2500/20 | 6259 | 87.5 | ||

| 2500/22 | 6679 | 96.3 | ||

| 2500/24 | 7099 | 105 | 13 | |

| 2500/26 | 7519 | 113.8 | ||

| 3000/8 | Φ3800 | 4050 | 48 | 11 |

| 3000/10 | 4650 | 60 | ||

| 3000/12 | 5250 | 72 | ||

| 3000/14 | 5850 | 84 | ||

| 3000/16 | 6450 | 96 | ||

| 3000/18 | 7050 | 108 | 13 | |

| 3000/20 | 7650 | 120 | ||

| 3000/22 | 8250 | 132 | ||

| 3000/24 | 8850 | 144 | ||

| 3000/26 | 9450 | 156 | 15 | |

| 3000/28 | 10050 | 168 |

Related Products

Related Information

Inquire