This equipment combines drying and granulating two functions together. According to requirements of producing techniques, pressure ow, spray hole size and ux of liquid material’s nozzle can be adjusted,granuled…

0086-18962409901

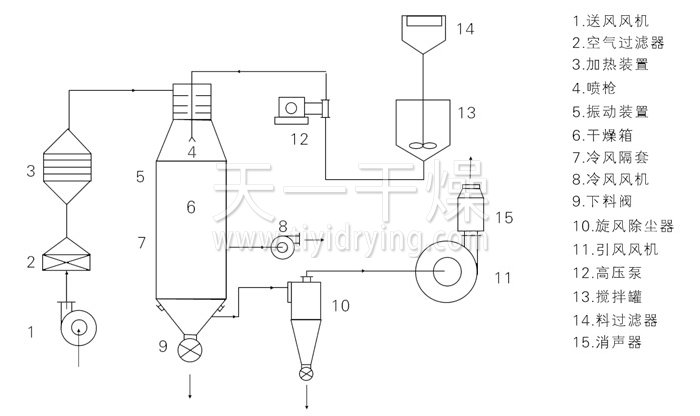

The YPG Series Pressure Type Spray (Congeal) Dryer has a device that can function drying and granulating together. The spraying pressure, spraying flow and the size of spray nozzle of the liquid material pump can be adjusted according to the requirements and the specific size of granule balls can be achieved.

Food Industry: Fatty Milk Powder, Protein, Cocoa Milk Powder, Subsitute Milk Powder,Egg White (Yolk), Food And Plant,Oats,Chicken Juice, Coffee, Instant Dissoluble Tea ,Seasoning Meat,Protein ,Soybean,Peanut Protein, Hydrolysate, Sugar,Corn Syrup,Corn Starch,Glucose, Pectin,Malt Sugar, Sorbic Acid Potassium, and etc.

Pharmaceutical Industry: Chinese Traditional Medicines, Pesticide, Antibiotic, Medical Drinking Agent,and etc.

Plastics and Resin: AB, ABS Emulsion, Uric Acid Resin, Phenolic Aldehyde Resin, Urea-Formaldehyde Resin, Formaldehyde Resin, Polythene, Poly-Chloroprene, And etc.

Detergent: Common Washing Powder,Advanced Washing Powder,Soap Powder, Soda Ash, Emulsifier, Brightening Agent, Orthophosphoric Acid, and etc.

Ceramic: Aluminium Oxide, Ceramic Tile Material, MagnesiumOxide, Talcum, and etc. Other: Calmogastrin, Hime Chloride , Stearic Acid Agent, and etc.

2. The finished product is ball granulewith uniform size. It's fluidity and solubility are good. The quality and purity of the product is very high.

3. Depend on the characteristics of raw material, the dryer can use hot air to dry or use cool air to granulate.

4. Simple and stable operation. The control system is con venient which is easy to realize automatic operation.

| Item \ Model | Unit | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

|

water evapo-

ration capacity

|

kg | 50 | 100 | 150 | 200 | 300 | 500 | 1000 |

|

overall dimension

(Φ×H)

|

mm |

1600×

8900

|

2000×

11500

|

2400× 13500 |

2800×

14800

|

3200×

15400

|

3800×

1880

|

4600×

22500

|

|

high-pressure

pump pressure

|

mPa | 2~10 | ||||||

| power | KW | 8.5 | 14 | 22 | 24 | 30 | 82 | 30 |

|

inlet air

temperature

|

oC | 140~350 | ||||||

|

product water

contents

|

% | <5(accessible 0.5) | ||||||

| collection rate | % | >97 | ||||||

| electric heater | KW | 75 | 120 | 150 |

temperature is lower than 200,the

parameters should be calculated

|

|||

|

electricity

+steam

|

Mpa+KW | 0.5+54 | 0.6+90 | 0.6+108 | according to the practical condition | |||

| hot air furnace | Kcal/h | 100000 | 150000 | 200000 | 300000 | 400000 | 500000 | 1200000 |

* The above is the largest evaporation.

Related Products

Related Information

Inquire